Die-cutting is a manufacturing process that uses die to cut materials in different shapes, designs, and patterns. The most common is a folding carton, otherwise referred to as a die-cut box. Die-cut boxes are popular in the custom packaging industry. They’re a cost-effective way to produce branded, customer-centric packaging with personalization options.

Small businesses prefer to use die-cut carton boxes for several reasons. These types of packaging boxes are easy to make. They combine convenience and practicality in an elegant solution. In addition, die-cut boxes are sturdy, lightweight, and contain a large capacity. Their many features make them versatile to use in different industries. Best of all, die-cut boxes are cost-effective if you order in large quantities.

Here is an in-depth guide about die-cut boxes and their characteristics:

What is a die-cut box?

A die-cut carton box uses a die to cut the packaging materials into a precise shape and design. A die is a specialized tool that cuts packaging. There is often confusion between a ‘die’ and a ‘dye’ due to their similar names. However, they are not the same items. A dye is a chemical substance. In contrast, a die is a piece of metal equipment.

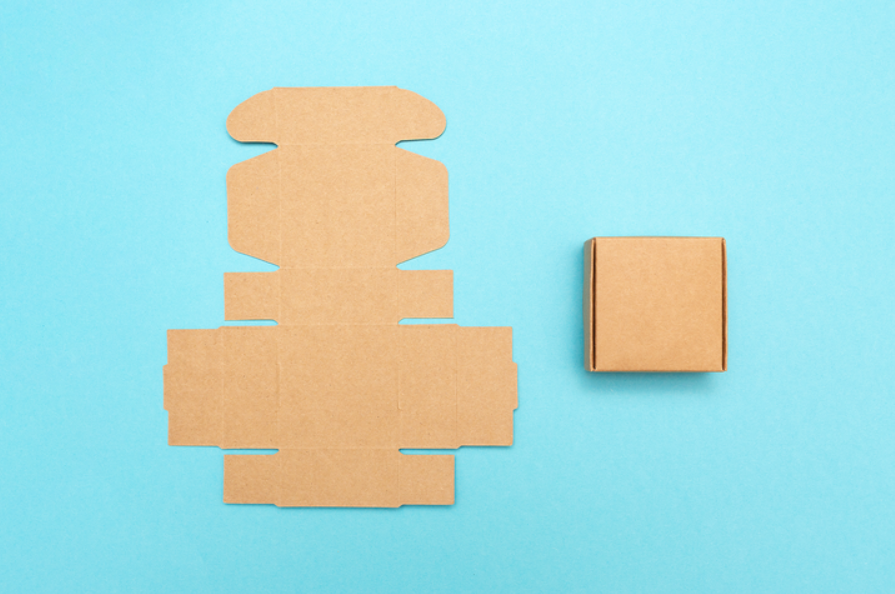

The die has a specifically designed shape, which determines how the box looks after cutting it. First, you mount the die onto a press. Then, you can start cutting different types of paper and cardboard. The final result is a die-cut box with the particular shape you envisioned. With a single die, you can produce thousands of identical-looking carton boxes. It’s an excellent way to standardize the manufacturing process for your packaging.

How are die-cut boxes made?

lved in the die-making process. First, you use the software to create a digital drawing. Then, it is burned into the die board with a digital laser cutter to make a precise outline. Before anything is laser-cut, everything must be measured and mapped accurately. All cut lines, fold lines, bleed lines, and safe zones are indicated in the drawing.

Once you have the die board, it sits underneath the material during die-cutting. It ensures accurate placement and minimal movement during the die-cutting process. The die board provides a guideline for the blade to make precise cuts. In addition, the die-cutting process allows you to customize the box with extra features. You can create through cuts, scores, creases and perforations.

Through cutting

Through cutting makes cuts through the packaging material. This process cuts away shapes and eliminates the surrounding material.

Scoring

Scoring goes about half as deep into the material as through cutting. However, it doesn’t go all the way, leaving behind an indent.

Creasing

Creasing also cuts about half as deep into the packaging material as through cutting. In addition, it creates an inward bulge around the fold line. This crease reduces stress on the packaging.

Perforating

Perforating involves creating a series of small holes in a designated section. For example, you can create a line formation on the packaging box.

Die-cutting

You use a die-cutting machine to firmly press the die board into the material. Doing so cuts the packaging material into its specified shape. When finished, you will have a complete die-cut box.

Designing

Lastly, you fold the die-cut box into its specified shape. Afterwards, you can decorate the box with additional labelling, stickers, branding, ribbon, or packaging accessories. Premium and luxury brands often use the die-cutting process to include fancy finishing touches. Embossing, UV printing, and foil stamping add a premium feel to the carton packaging.

Benefits of die-cut boxes

Die-cut boxes are known for their elegant aesthetic and affordable costs. In addition, they provide sturdy protection for your custom shipping boxes. The die-cutting ensures your box is the perfect fit based on the product’s shape and dimensions. Due to the precise customization, you can use fewer packaging materials to cushion and present the product. That lowers your costs and reduces waste output.

Die-cut boxes are also beneficial due to their versatility. You can die-cut a wide variety of materials, from paper to neoprene. In addition, you can create die-cut boxes out of plastic, polyester, foam, metal, cork, and silicone.

In addition, die-cut boxes are a way to cut down on large-volume, long-term packaging costs. They allow you to create unique custom packaging. You can use colour, labelling, texture, and packaging preparation to craft the optimal brand narrative for the customer. With die-cut boxes, you are limited by nothing except your creativity.

The world’s most successful companies use die-cutting techniques daily to produce their packaging. Any small or medium-sized business can do the same with die-cut boxes, making a significant impression on customers. You can rely on die-cut boxes for a high-quality, premium-grade presentation that suits your brand.